Posted by Victoria on 18th Aug 2023

Welcome to the new Cashmere Centre Blog!

Welcome Dear Readers, to our wonderful new blog!

Now seems the perfect time to introduce our little chat, as our website has had a lovely little update, so a blog is a welcome new addition for you to read at your leisure.

What to expect...

In this chat, I will take you through the journey our styles make, from initial ideas, inspiration, and research to the end result of a new luxury piece of cashmere knitwear. From grandmothers' lovingly hand-knitted sweaters to runway showcases at fashion weeks, knitwear has woven its way into the fabric of our lives.

Through its history, techniques, and contemporary adaptations, we've witnessed the enduring charm and versatility of this textile and I have been lucky enough to be part of that journey with Cashmere Centre.

So, dear readers, join me as we embark on a cozy and enlightening journey through the world of our knitwear – a journey that celebrates tradition, innovation, sustainability and the warm embrace of fashion that feels like home.

The team behind the designs and catalogue...

The face behind the brand is Sarah. She works very hard to ensure your catalogue is correct, interesting and that stock is on the shelf! We have been working together for many years. We even wear the same clothes (note the T shirts!

I have been designing for Cashmere Centre for 12 years now, which has flown by!

My background of art and design has helped , but I owe my knowledge to two main sources. I was lucky enough to be trained by one of knitwear’s finest, Mr Colin Grahame. An engineer by trade, Colin has been part of the knitting world for decades. Helping the likes of Laura Ashley and some of the biggest names in Scottish knitwear, such as Balentines, what he doesn’t know about knitting, just isn’t worth knowing!

The old school is always the best school!

I have spent many an interesting hour with him in knitting tutorials, absorbing his knowledge of the techniques (there are so many!), yarns, plys, dye, needles, specifications and much more.

He gave me the passion for the industry and I still follow his guidance to this day. I have kept all the scribbles of notes I have taken over the years, and still refer to them! Colin’s generation of the ‘hands on’ approach is sadly, coming to an end with the introduction of super machines and IT technology, but I hope that I can pass on his knowledge and keep the old traditions of knitwear standards alive in the future.

Introducing our knitters...

My second source of knowledge and some of my favourite people in the world, are the wonderful staff at our factory in Kathmandu, Nepal. I have been working along side them for over a decade, and have watched the factory grow, modernise and endure this fast-paced world of knitwear fashion.

Santosh and Suresh Gurung run the factory together, Santosh is more the business side and yarn expert, while Suresh is the genius with the knitting itself. Self-taught through books, internet, and in house training from an elder in the factory, he is the go-to man with any problems or advice needed.

Nitesh is my right-hand man. We have almost daily contact, and without his guidance with my myriad of questions, I most definitely would be at a loss! Nitesh and I have grown in our roles at the same time and know exactly how each other works, which is so important in this industry.

Having the relationship we have is very precious to us all. We are super proud of our guys over in Nepal, they are extremely skilled and creative and just love to join in and help, even when I throw particularly wild ideas at them!

The Journey Begins...

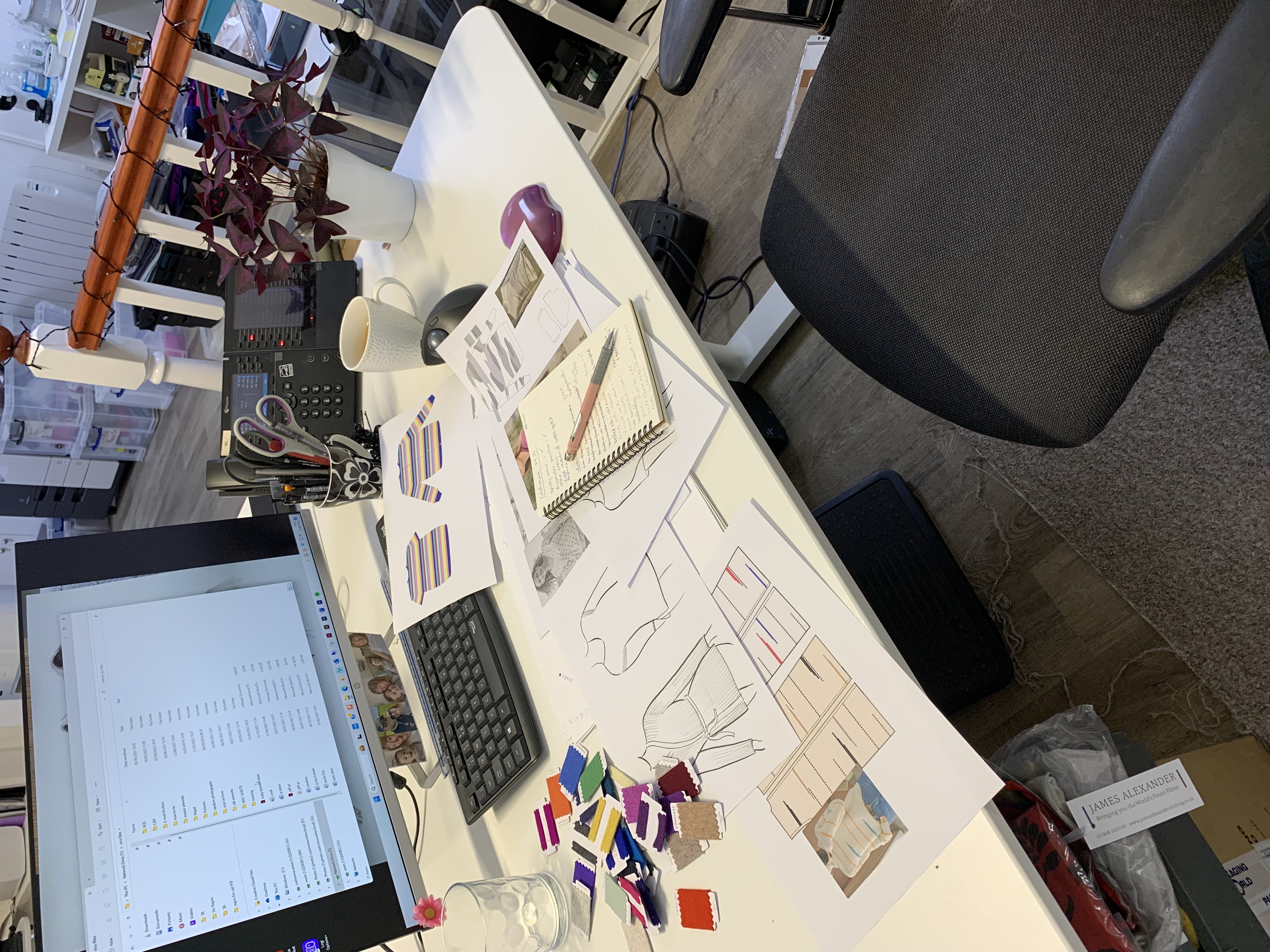

Work on the range for spring 2024 has begun! My first job is to do the legwork, research into what’s trending and what’s selling.

Prior to my role as designer, I spent 3 years talking to you, our customers, every day, taking orders and learning what you all like, and don’t like!

All my designs are targeted at our demographic, using the feedback I have accrued over time, and also trying to keep the ideas fresh and modern.

I fully understand the mature woman doesn’t want to look frumpy, or older than she is, so my designs need to add glamour and femininity. Range is hugely important too, as being mail order, we have all types of ladies shopping with us, so I need to add variety too. Length, fit, colour, weight, all these factors are essential and should be considered in our range .

Time to Draw the Idea...

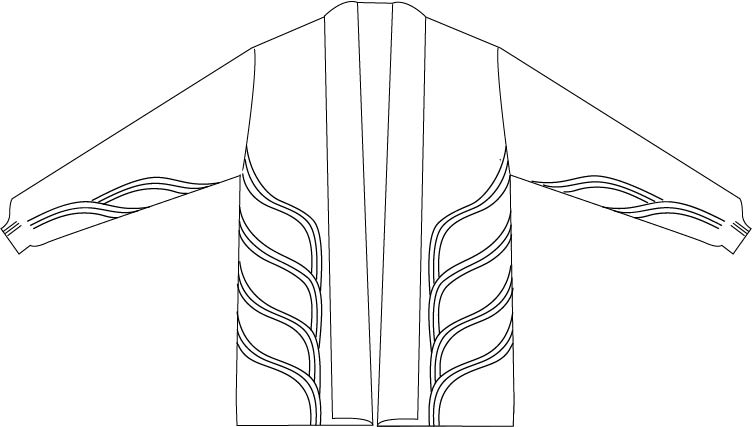

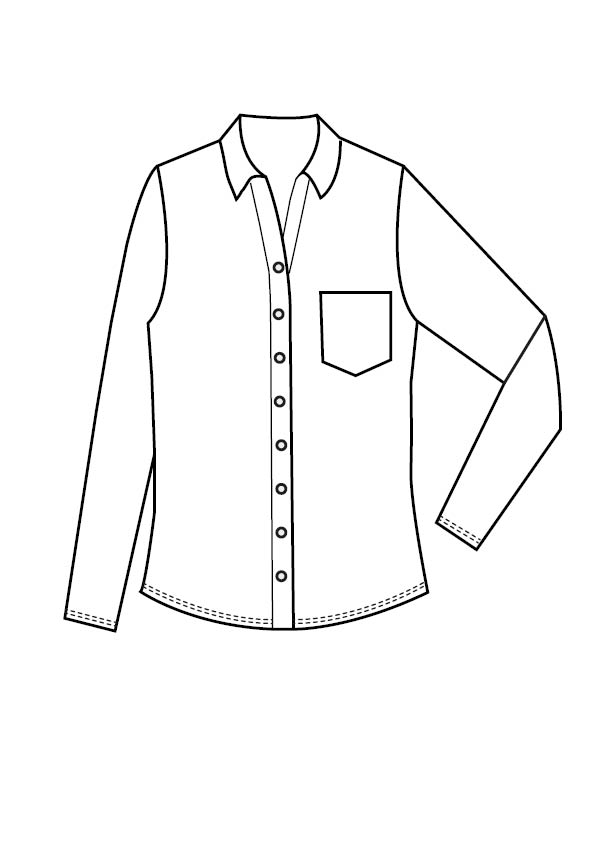

Once I have the idea, it needs to be drawn. Here I must apologise. I definitely am not that wonderful fashion designer that can draw these stunning illustrations of catwalk models! Mine are far more utilitarian and specific to the knitters, so CAD (computer aided design), or simple sketches is how we work best to get the details right.

I need to show the trims, rib finishes, pocket information and silhouette clearly for our knitters to follow. Many things need to be considered here too. Comfort, hang, button placement, ply and any embellishments, such as cables or ribbing.

Once I am happy with the final look, I put the information onto a spec sheet and fire it off to Nitesh in Nepal to begin the sample stage.

Coming next....

In my next update I will take you on the factory journey of how your garment is made, and the stages needed to produce the best cashmere knitwear. See you soon cashmere lovers!

Welcome back cashmere lovers!

As promised, here is the journey one of our garments makes, from the first stitch, to the garment bag as a perfect finished piece of treasured cashmere.

Knitting in general, is now done on large industrial machines, but just a few years ago we were using traditional wooden looms to make each panel by hand. Over time more and more of the knitting machines were purchased, and a far more effective work schedule was created.

All our garments are knitted this way now, except for one or two highly specialist hand knit requests.

Hand knitting was very time consuming and relied on a huge workforce. Also, the consistency from garment to garment was harder to control, due to the hand made nature of each garment. Cashmere knitting is technically called fully fashioned. This is knitting without waste, so each panel is 'fashioned' into the shape needed, not cut from a panel.

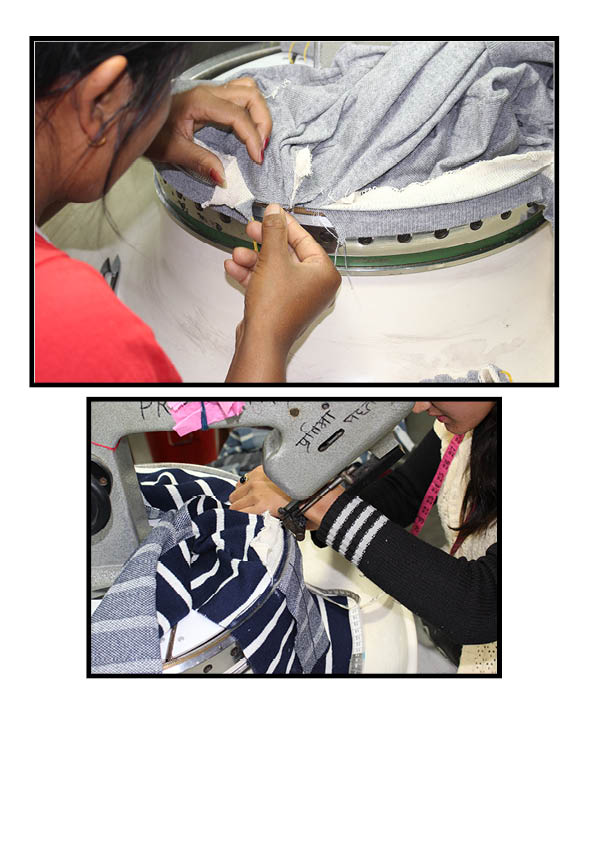

Next, after each panel has been finished in the knitting machine itself, it goes off to be linked (knit - not sewn ) in the linking procedure. The knit loop linking provides stretch and comfort through all the joints. Unlike cut and sewing - the sewing stiffens the knitwear.

This is a very skilled area, and takes many months, if not years to learn how to link professionally.

Linking means that one individual stitch of one piece, is linked through a needle to the corresponding stich on the next panel. That’s arms to body, neckline to body, plackets and strapping. All need linking together with matching cashmere yarn.

After linking, it goes to the hemming process where the joints of the garment is hand sewn, such as at the sleeve, the bottom, underarm and neck of the garment.

Once the hemming and finishing is complete, off it goes to the wash house! Here is the science! In knitwear terms, washing a newly made garment is called milling. This must be at the precise temperature, time and heat.

The garment is dipped in a hot water solution containing cashmere shampoo with a temperature of 45°. It is dipped for 15 minutes and stirred by hand every 5 minutes. It is then dehydrated with a hydro-extractor. Again washed in mild water and dried in a tumbler dryer with below 65° temperature.

If any one of these is incorrect, the garment fibres will be effected, which can lead to pilling later in the garments life. Washing correctly means to lift the fibres of cashmere above the surface, just enough to feel the softness, but not so much you can see pure fluff. Again, this takes years of training to perfect.

This wonderful vintage image is of the milling process as it used to be, these men were experts in just feeling the correct handle. Better than any machine!

Once spun to release water and dried the garment needs to be sent for first stage finishing. Here the pockets are attached, buttons applied, and holes made for the buttons. The weak points on the garments are strengthened, such as seam joins in the arm pit and shoulder.

Buttons are hand dyed to colour match the garments if that is required. Nylon, metal, shell and we also use bone, which is a by-product of the yak farming, meaning there is less waste, even the bones!

Once dressed with its buttons, zips and pockets complete, its off for a steam press.

Pressing is the final stage to create that finished shape that is permanent. Here it is vital to be accurate. Measuring all the time to get the size correct and ensure all the seams are flat, correctly placed, and equal.

Once pressed, the sweater then must rest for a good 24 hours, to release the steam and moisture. Then its off to have neck and side labels hand sewn in, then bagged up for shipping.

This whole process takes around a week, but we account for two weeks for full production of garments. Shipping is then organised and its take off!

When you purchase a garment that is out of stock, we quote up to 28 days for re stock, and this is why. The process can’t be rushed, and we hope you will agree, the wait is worth it!

Next time we will be talking about a word that is on everyone's lips - sustainability and animal care.

See you soon cashmere lovers!